I had planned to go Turkey Hunting in the backwoods of Alabama Saturday morning. That got delayed and I ended up riding around with my old friend in the Miata with the top off. Ripping through the gears on the back country roads with new tires on the rear brings grins ear to ear. As 7 yr old kid packed in the back seat of an old blue Ford Escort with my little sister, I had always dreamed of driving a red sports car to Grandmas house – finally happened.

In addition to breaking the 870 down so it would fit in the trunk of the Miata, I also brought the 6mmARC, the Ruger 10″ 22s, and the CZs (ZomBullShadow, SP-01 Racegun, 97B mostly stock). I had planned to also do some target shooting and test some new loads in addition to turkey hunting. – all the gear packed to the gills in the Nimble Ninja (a common occurrence). I decided to stop in just after lunch at Bob Gibson’s Original BBQ house and with Swann Creek WMA range was only 15mins detour on the way back home made it an easy decision.

It was perfect weather, and I was shocked to see the range not even half as full as last time on a Saturday. Parked at the 100 yd pavilion and signed in. I had been suffering a putrid cough and loss of voice – shouldn’t be COVID as I can still smell and taste plenty, but it wasn’t fun – I braved through it and kept my distance.

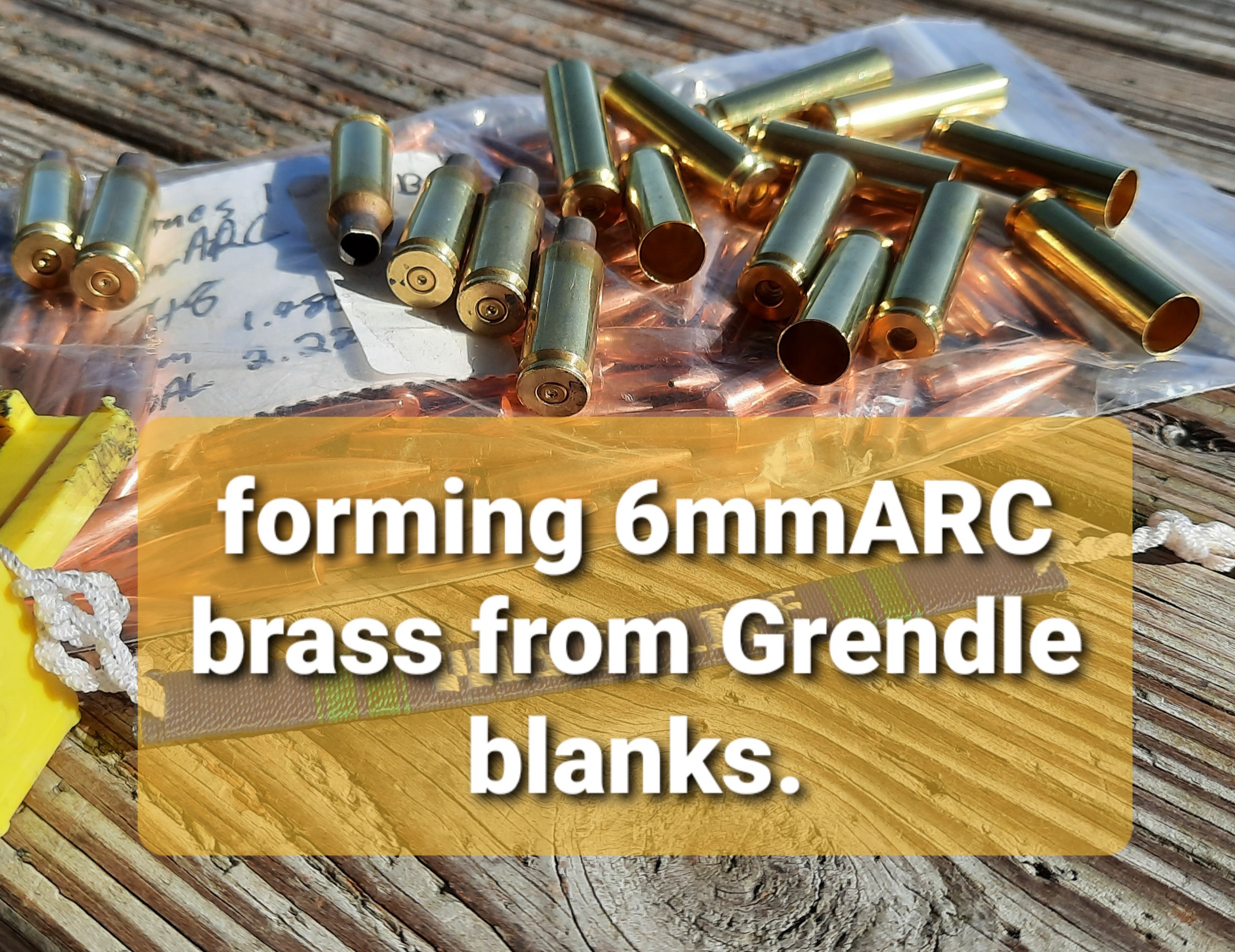

First up, was the 6mmARC, confirming my “Jam the Lands” load, which worked very well to fire form about 20 cases of converted 6.5 Grendel Basic Brass. Worked great, I thought the single feeding would be an issue but it wasn’t bad at all. A friend happened to be there with his LabRadar, which brings up a question – aren’t all people with Lab Radars considered friends?

We confirmed the velocity of the of my settled load of Leverloution over 105 Bergers to be ~2550fps. I let him shoot a mag and try the rifle and got video using the ATN. Chased down all brass and it looked good. So next is loading a single case until the neck is split (4-8 times will be my guess). Then try same test using the annealer after each firing.

Next up was the 10″ Rugers. First was the Black Grand-Mamba (scoped). I sighted in at 50 yards and made some adjustments to the scope. It shot very well but then I noticed a bit of slop that I thought was coming from the push button release, but it was actually the scope mount coming loose off the receiver ( I don’t think I locktighted them). Next up was my Bond gun – the Stainless MKII 10″ barrel version with stock trigger and gold Vol Bolt.

It shot good but did have some light strikes which the MK4 finished no problem. I started shooting at small items on the 100yd berm. I was Benched and bagged so it wasn’t very difficult to get the berm targets to dance around a bit. Mostly close/about 2″ off, but also some direct hits.

I was holding the front post about 1/8″ high off the rear sight and using CCI SV factory 2nds. I did notice that hits on self healing plastic targets at this distance did not make the target move very much/at all.

Lastly was the CZ pistols, which the 97 ruled the day. I started with the ZomBullShadow, and the 90gn ammo I had just made. It did not have enough power to cycle the gun.

Switched to new Berrys 115 load and they would BARELY cycle the gun and would ONLY cycle with firm grip (great example of limp wristing).

I DID get one of the bullets to jam the action up tight. looks like the offending round did not get sized or plunked. Bagged the pistol and swiched to SP-01. Quickly realized that my dot battery was out so switched to the 97. 50 roudns of the Standard RN loads and it shot great.

Loads tested:

9mm 90gn Hornady hollow points with nickel cases. They fired fine, shot like a 22, but didn’t have enough oomph to fully work the slide. This resulted in the case being held in by the extractor and not even hitting the Ejectorm just stayed along for the entire ride, keeping perpendicular to the slide, not picking up the next round and jamming the gun with the brass hitting the breechface just a tad off center. But, the highest load that I used I believe DID work the slide, and I remember checking the brass and it seemed OK, cratered, but not pierced – so need to finish making those (~150 bullets) at highest TESTed powder charge and do accuracy/function testing with the Ruger PC9.

The Berrys 115 gn seemed to run GREAT in the ZomBullShadow – at first. Then I got a round that hadn’t been sized at the base and it jammed the gun. I did get to shoot about 3 mags of them and they ran great. The round that locked the gun probably didn’t get sized properly/all the way(short stroking the press when getting case feed adjustements setup maybe) Either way need to plunk all rounds for the gun. The gun was bagged and dis assembled at home, looks GTG now.

Next up was the SP-01 Racegun! – This gun Would have ran great BUT, I left the Dot ON and the battery was dead. DANG!

The 97 came out and reigned supreme on that day. 4 mags shot GREAT with the stock 45 loads I had made (Berrys 230RN over Alliant Power Pistol). Called that a day and packed up to head home.

Other notes and observances: There was one 9mm round that was right on the edge of performing/running the slide. I remember limp writing one of the dev loads and the gun would jam – firm grip it would run. I went back and forth a few times to confirm. I have had a couple of light development loads exhibit this issue before, but not quite this evident. It was actually kind of cool, to be able to make the gun jam jut by having a slightly softer grip, but I don’t ever want to load action match rounds on that hair line verge of not working, better to powder up!